Imagine you have a great product idea and you’re eager to bring it to market. Where do you start? For many beginner importers, sourcing a product can feel like navigating a maze for the first time. This is where end-to-end sourcing comes in. In this friendly guide, we’ll explain what end-to-end sourcing is, why it’s important, and walk through each stage of the sourcing journey – from the initial product research all the way to delivery. Along the way, we’ll share real-world examples and mini case studies so you can learn from common pitfalls and best practices. By the end, you’ll understand how an end-to-end approach can make sourcing simpler, more efficient, and less stressful for both new entrepreneurs and growing businesses.

What is End-to-End Sourcing?

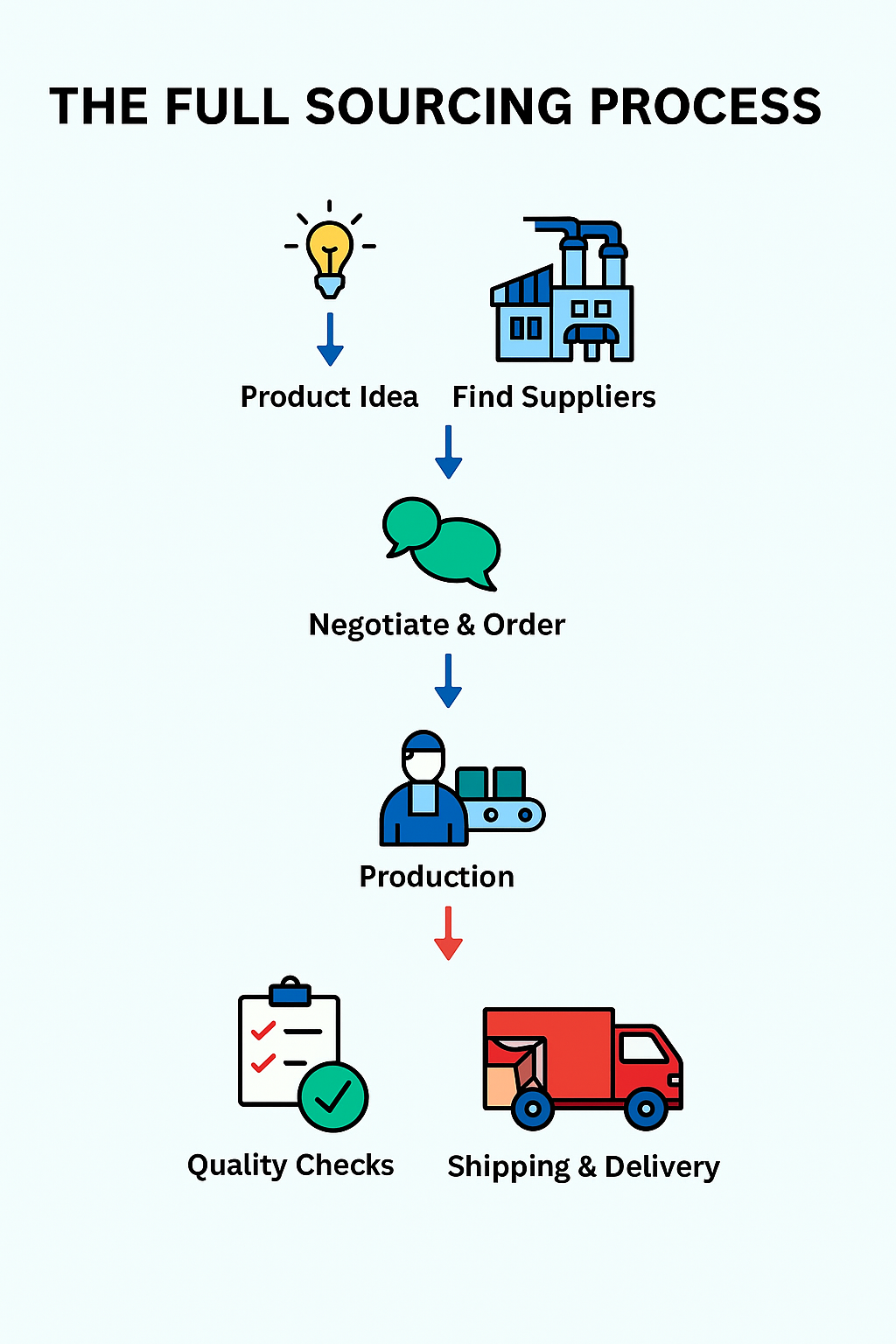

End-to-end sourcing means managing the entire product sourcing process from start to finish as one integrated workflow. In other words, it covers all stages of sourcing, from the moment you identify a product need or idea to the moment the product is delivered to your door (or warehouse). This comprehensive approach links every step – product research, supplier selection, negotiations, quality control, shipping logistics, and more – into one smooth process.

By treating sourcing as an end-to-end journey, nothing gets overlooked or left to chance. It’s like having a roadmap for every step required to get your product made and delivered. For example, rather than just finding a supplier and hoping for the best, an end-to-end approach ensures you also handle things like prototype testing, freight shipping, customs paperwork, and final quality checks. It’s a holistic game plan for procurement that leaves no loose ends.

Why is End-to-End Sourcing Important?

Taking a holistic, end-to-end view of sourcing is important because it saves time, money, and headaches in the long run. Businesses that implement end-to-end sourcing often see significant cost reductions and efficiency gains. By planning ahead for each stage, you can avoid expensive mistakes – like discovering quality issues only after products arrive, or scrambling to find a last-minute shipper.

End-to-end sourcing also helps manage risks and improve supplier performance. For instance, it encourages regular supplier assessments and quality checks, which in turn increases on-time delivery rates and prevents supply disruptions. In short, being thorough at each step means fewer unpleasant surprises.

Equally important, an end-to-end approach promotes better communication and collaboration. Sourcing a product involves multiple players – suppliers, inspectors, freight carriers, customs agents, etc. Coordinating all these moving parts can be challenging. An integrated approach improves transparency and teamwork, so everyone stays on the same page. The result is a smoother supply chain and stronger relationships. Businesses that source proactively and collaboratively tend to make better decisions and have more reliable outcomes.

Finally, end-to-end sourcing gives you greater control and visibility. You can track progress at each milestone (from production status to shipping updates) and respond quickly if something needs attention. Especially as your business grows, this full-picture visibility is invaluable for scaling up without losing control. In today’s fast-paced market, being able to adapt and manage the entire sourcing process is a big competitive advantage.

Sourcing with vs. without an End-to-End Approach

How different is it to use an end-to-end sourcing strategy versus a piecemeal or “do-it-yourself” approach? Let’s compare two scenarios:

Without End-to-End Services (DIY)

You handle each step separately on your own. For example, you find a factory on a supplier directory, negotiate pricing yourself, arrange inspection later (if you remember), then figure out shipping and customs at the end. It can work, but you’ll be juggling multiple contacts and tasks. New importers often find this overwhelming, and important details can slip through the cracks. In fact, diving into overseas sourcing without guidance can feel like “a complex maze, riddled with hidden obstacles” – from language barriers to quality mishaps. If you lack experience, the DIY route may lead to costly mistakes (wrong materials, delayed shipments, regulatory issues, etc.) that eat into your profit and timeline.

With End-to-End Sourcing Services

You (or a dedicated partner) manage the process as a cohesive whole. Often this means having a sourcing agent or service that oversees all stages for you. Instead of contacting ten different people, you might have one point of contact coordinating everything – from vetting the factory to booking freight. This integrated service ensures each step is handled at the right time and nothing is missed. For example, if you use an end-to-end sourcing agent, they will likely help research your product, find reliable suppliers, negotiate the best terms, inspect the goods, and arrange shipment door-to-door. The process becomes much more streamlined. You gain peace of mind knowing experts are managing the tricky parts (like factory audits or customs clearance), while you stay informed through a single channel. Essentially, end-to-end services let you focus on your business without getting bogged down in supply chain hassles.

(Image: Side-by-side comparison illustration of managing sourcing by yourself versus using an end-to-end sourcing service, highlighting the multiple touchpoints in DIY vs. the single streamlined pipeline with end-to-end.)

In summary, a DIY approach might save service fees, but it demands significant time, know-how, and risk management on your part. An end-to-end approach, especially with experienced partners, may cost a bit more upfront but greatly reduces risk and errors, often saving money in the long term by preventing issues. Many growing e-commerce businesses find that end-to-end sourcing is “worth it” for the efficiency and reliability it brings.

Stage 1: Product Research and Planning

Every successful sourcing journey begins with thorough product research and planning. This stage is all about deciding what you need to source and how to approach it before you start contacting suppliers. Skipping this step is like setting off on a road trip without a map. Key tasks in Stage 1 include:

Identify Your Product and Market Needs

Clarify what product you want to source and why. Who is your target customer? What problem does the product solve? For example, a new importer might research trending products in a niche (say eco-friendly kitchenware) and zero in on a bamboo travel mug that’s in demand. Understanding the market ensures you choose a viable product.

Define Specifications and Quality Requirements

Determine the features, materials, and quality level your product must have. This could mean deciding on dimensions, material type, certifications needed (e.g. FDA approval for a food-contact item), packaging requirements, etc. Clear specs will guide suppliers and later stages like quality control.

Budgeting and Cost Targets

Estimate your target cost per unit and overall budget, including not just manufacturing but shipping, duties, etc. Having a cost target helps in evaluating supplier quotes later. For instance, if you know similar products sell for $20 retail, you might aim for a production cost under $5 per unit.

Timeline Planning

Consider your timeframe. When do you need the products in hand? Working backward, plan roughly how much time to allow for each stage – e.g. product sampling (a few weeks), production (maybe 30-60 days), shipping (another few weeks for ocean freight). This will set realistic expectations when negotiating with suppliers and scheduling your launch.

Taking the time to plan upfront makes the rest of the sourcing process much smoother. As a quick example, Case Study – Jane’s Planner: Jane, a first-time e-commerce seller, decided to import custom planners. In the planning stage, she researched popular planner designs, identified must-have features (durable cover, thick paper, a certain binding style), and calculated she could spend up to $4 per planner to hit her profit goals. She also noted key seasonal deadlines (needing inventory by August for the back-to-school rush). With this prep work done, Jane had a clear roadmap and criteria before contacting any manufacturers – a move that saved her from chasing unfit suppliers later on.

Stage 2: Supplier Sourcing and Vetting

Once you know what you need, it’s time to find the right supplier to make your product. Stage 2 is all about supplier sourcing and vetting – essentially, finding potential manufacturers and checking that they are trustworthy and capable. This stage is crucial, as choosing the wrong supplier can doom a project before it even starts.

Finding Suppliers

Start by searching for manufacturers or suppliers that produce your type of product. You can use online directories and marketplaces (for example, Alibaba, GlobalSources, ThomasNet), attend trade shows, or even get recommendations from industry contacts. At this stage, cast a wide net: you might shortlist several suppliers to compare. Look for clues about each supplier’s capabilities, such as their production range, years in business, client reviews, and any certifications (like ISO quality certificates) they hold.

Initial Outreach

Contact the shortlisted suppliers to gather more information. A common approach is to send a Request for Information (RFI) or an inquiry email detailing your product requirements and asking key questions. Notice how responsive and clear each supplier is in their communication – this can be an early indicator of their professionalism. Also, confirm basic details like: Are they a factory or a trading company? What is their minimum order quantity (MOQ)? Do they have experience exporting to your country? Misrepresentations can happen, so it’s okay to ask for evidence like factory photos or references.

Evaluating and Vetting Suppliers

Once you have initial quotes and conversations going, evaluate each supplier against your criteria. Important factors include: product quality, pricing, production capacity (can they make the quantity you need on your schedule?), reliability, and compliance. At this point, many experienced sourcing managers will perform some form of due diligence. This could involve checking the supplier’s business license, looking up any online reviews or blacklists, and verifying they indeed specialize in the product (for example, if a company offers everything from electronics to clothing, they might just be a middleman). Some companies even hire third-party firms to do background checks or factory audits. In fact, about 85% of successful sourcing processes include a supplier audit or qualification check before finalizing a contract.

Think of vetting as “trust but verify.” For instance, if a supplier claims to have a big factory, you might request a video tour or live video call walkthrough of their facility. If they boast of strict quality control, ask about their QC procedures or certifications. This stage might feel tedious, but it can save you from nasty surprises later (like discovering your supplier outsourced the work without telling you).

Example – Vetting in Action

Let’s continue with Jane’s planner project. She found five potential planner manufacturers on Alibaba. After contacting them, two stood out with good English communication and reasonable prices. Before jumping in, Jane did some vetting: she checked that the companies were verified suppliers on Alibaba and asked for photos of their production lines. She also requested contact info for a past client as a reference. One supplier hesitated to provide any references or details, which raised a red flag, so she dropped them. The other supplier willingly shared factory pictures and even offered to do a video call showing their printing machines. That transparency gave Jane confidence that this supplier was genuine. By the end of Stage 2, she had one promising supplier shortlisted for the next steps.

Stage 3: Requesting Samples and Evaluating Quality

With a likely supplier (or a couple of finalists) in mind, the next stage is to get samples of the product and evaluate them. Stage 3 is all about sampling and quality evaluation before you commit to a large order. This step lets you “try before you buy” on a small scale, which is critical for verifying that the supplier can deliver what you want.

Request Product Samples

Ask your chosen supplier to send a sample unit (or a few units) of the product. It’s normal to pay for samples and shipping, so don’t be surprised if the supplier charges a fee – think of it as an investment to check quality. If your product is custom-designed or has your branding, you might start with a prototype or pre-production sample. For example, Jane requested two sample planners with her proposed cover design and paper specs. It took about 2 weeks for the factory to produce and send them to her.

Testing and Feedback

Once the sample arrives, inspect and test it thoroughly. Does it meet the agreed specifications? How is the build quality, material feel, packaging, etc.? It can help to compare it against competitors’ products or any benchmarks you have. In Jane’s case, she examined the sample planner’s paper thickness, binding strength, print clarity, and durability of the cover by using it for a few days. She also sought feedback from a friend (target user) to see if it met expectations. If any aspect is not satisfactory, now is the time to discuss it with the supplier and see if adjustments can be made.

Iterate if Needed

It’s not uncommon to go through multiple sample iterations before the product is just right. Don’t hesitate to request changes and a revised sample if needed. A good supplier will work with you to refine the product. For example, if the sample mug’s color came out wrong or a gadget’s part didn’t fit perfectly, you can communicate this and have the supplier tweak the process or materials. This back-and-forth ensures the final production will meet your standards. Keep in mind, each iteration takes time, so factor that into your timeline.

Evaluate Supplier’s Cooperation

Sampling is also a test of the supplier’s cooperation and reliability. Pay attention to how they handle this process. Are they receptive to feedback and willing to improve? Do they deliver the sample in the promised time? A supplier who is responsive and quality-conscious during sampling is likely to be a good partner during mass production. On the other hand, if they dismiss your concerns or the sample quality is far off from what was promised, that’s a warning sign to reconsider the partnership before you invest in a full order.

Real-world mini story: “The Sample That Saved the Day.” A small electronics startup once planned to order 5,000 custom phone chargers from a new overseas supplier. The specs looked good on paper, so they almost skipped the sample step to save time. Luckily, they decided to test a sample first – and discovered the charger overheated during use, failing safety tests. The supplier had used a substandard component. Because the issue was caught at the sample stage, the startup avoided a potential disaster (a whole batch of unsafe products). They worked with the supplier to fix the design and get a proper sample, ensuring the final product was safe. This story shows how sampling can literally save your business by catching quality issues early.

Stage 4: Negotiation and Order Confirmation

After you’re satisfied with a sample and confident in the supplier, it’s time to talk business and place the order. Stage 4 involves negotiating the final terms and confirming the order (often through a purchase contract or proforma invoice). This stage sets the foundation for a smooth production run, so it’s important to get the details right.

Negotiating Price and Terms

Even if you received a price quote early on, now is the moment to finalize pricing based on your intended order quantity and any adjustments from the sampling phase. Don’t be shy about negotiating – suppliers expect it. Key points to negotiate include the unit price, payment terms, production lead time, shipping terms (e.g. FOB or EXW), and any included extras (like spare parts or replacements for defects). If your order is large or you plan to reorder regularly, you have more leverage to request a better unit price or favorable terms. Effective negotiation can have a real impact – on average, good negotiations can reduce sourcing costs by 15–25%. For example, Jane is ready to order 2,000 planners. The supplier’s initial quote was $5 each for 500 units; with a larger order, she negotiates it down to $4.50 each, saving $1,000 overall. She also negotiates to pay a 30% deposit and 70% upon completion, instead of 50/50, to ease her cash flow.

Setting Clear Specifications in Writing

During negotiation, ensure all product specs and quality requirements are documented in the order contract. This should include details like materials to be used, packaging, any logos or branding placement, and the agreed sample as the quality benchmark. If you expect the supplier to follow certain standards or include specific components, put it in writing. This avoids ambiguity later. It’s much easier to hold a supplier accountable if the expectations are clearly spelled out in the purchase agreement or invoice.

Order Contract and Purchase Order

For sizable orders or new supplier relationships, it’s wise to have a formal contract or purchase order (PO) in place. The contract should list all terms: product details, quantity, price, payment schedule, delivery deadline, and clauses for what happens if something goes wrong (e.g. late delivery penalties, quality reject policy). Many businesses involve legal counsel to draft or review contracts, especially for international deals – in fact, about 95% of businesses use legal assistance in contract development to avoid future disputes. If a custom contract isn’t feasible, at least ensure the proforma invoice from the supplier contains all agreed terms and both parties sign/stamp it.

Initial Deposit

Most suppliers require a down payment (commonly 20-30% of the total order value) to kick off production. Be prepared to send this deposit as soon as the contract is signed, so the supplier can buy materials and reserve production slots. Use a secure payment method; for international deals, wire transfer is common, but platforms like Alibaba Trade Assurance or escrow services add a layer of protection. For example, Jane sends a 30% deposit to her planner manufacturer via Alibaba’s secure payment system, which holds the money until the supplier ships the goods, giving her some peace of mind.

By the end of Stage 4, you should have a firm agreement and order in place. This is a major milestone – congratulations! All the groundwork from earlier stages now translates into a clear plan that the supplier will execute. You’ve set expectations and secured terms that protect your interests. Now the focus shifts to making sure the production and delivery go as planned, which brings us to the next stages.

Stage 5: Production and Quality Control

With the order confirmed, the supplier will move into mass production of your product. During Stage 5, production and quality control go hand in hand. Even though the factory is doing the manufacturing, you (and potentially your sourcing partners) have an important role in monitoring quality to ensure the final goods meet your standards.

Production Monitoring

Depending on the complexity of the product and the relationship, production can take anywhere from a couple of weeks to a few months. It’s a good practice to stay in regular contact with the supplier during this period. Ask for status updates at key points. For large or critical orders, some buyers conduct a mid-production inspection (for example, checking output when 20-50% of goods are made) to catch any issues early. If you have a local agent or third-party in the area, they can visit the factory to observe production. For instance, Jane’s planner order has a 6-week production time. At week 3, she asks for photos of the assembly line and a report on whether things are on schedule. The images show the planners being printed and assembled, giving her confidence that progress is on track.

Quality Control (QC) Inspections

One of the most vital parts of end-to-end sourcing is implementing quality control checks before the products leave the factory. This usually involves a pre-shipment inspection – an examination of a sample of the goods (or all goods, depending on your arrangement) when production is complete or nearly complete. Many businesses hire professional QC inspectors or agencies to do this on their behalf. The inspector will visit the factory and use a checklist to test product specifications, functionality, appearance, packaging, and so on. For example, an inspector might randomly open 5 boxes out of 100, and from each, test a few units thoroughly. If any critical defects or widespread problems are found, the shipment can be put on hold until the factory fixes them. This step is so important that roughly 80% of businesses conduct pre-shipment inspections to ensure product specs are met. It’s much cheaper and easier to address issues while the goods are still at the factory than after they’ve been shipped overseas.

Addressing Issues

If the QC inspection reveals problems (say, a higher defect rate than acceptable, or a feature not made to spec), you should immediately discuss corrective action with the supplier. Depending on severity, the supplier might rework the products, provide a discount, or in rare cases you might cancel the order. Most suppliers want to avoid rejection, so they will try to resolve issues quickly if you have solid evidence from the inspection. In our planner example, let’s say the inspector finds that 10% of planners have a printing error on one page. Jane could ask the supplier to reprint those affected planners or replace them, delaying shipment slightly but ensuring quality. Having this conversation before shipment is key – once goods are shipped, your leverage drops.

Maintaining Communication

Throughout production and QC, keep communication lines open and friendly. Compliment the supplier on good work when things go well, and be clear and factual (not accusatory) if issues arise. Building a positive relationship can motivate the supplier to prioritize your order and perhaps go the extra mile (like carefully repacking items to protect them). This stage, when handled well, sets the tone for either a smooth delivery or, if neglected, can lead to a lot of fire-fighting later. By investing time in quality control, you’re essentially saving yourself (and your customers) from unpleasant surprises down the line.

Stage 6: Shipping and Logistics

Now that your products are manufactured and have passed quality checks, the next step is getting them from the factory to your hands. Stage 6 is all about shipping and logistics – arranging the transportation of goods and managing the journey across borders. This part can be complex, but with proper planning it’s manageable even for smaller importers.

Choosing a Shipping Method

First, decide on the mode of transport: Air freight or sea freight (ocean shipping) are the most common for international sourcing. Air is fast (a few days to a week) but expensive, typically used for smaller, high-value shipments or urgent timelines. Sea is slower (several weeks for transit) but much cheaper per unit, ideal for large volume or heavy goods if you have lead time. There’s also express courier (DHL/UPS/FedEx) for very small shipments or samples. In Jane’s case, her 2,000 planners fill about half a 20-foot container, so she opts for sea freight to keep costs low, as she doesn’t need them for another month.

Freight Forwarders

Coordinating an international shipment involves many steps – export paperwork, cargo booking, possibly consolidation, and dealing with carriers. This is where a freight forwarder can be a lifesaver. Freight forwarders are companies that specialize in arranging shipping and logistics. You provide them the details (pickup location, destination, goods info), and they handle the rest: booking space on a ship or plane, preparing export documentation, and organizing trucking if needed. They can also help advise on the best shipping routes or schedules. Many sourcing agents or end-to-end services will either act as the forwarder or collaborate with one to give you a turnkey solution. It’s possible to arrange shipping yourself directly with carriers, but for most importers, using a forwarder simplifies the process enormously.

Incoterms and Handover

When you negotiated the order, you hopefully agreed on an Incoterm – the international trade term that defines when the risk and cost transfer from the supplier to you. Common terms are FOB (Free On Board) where the supplier delivers goods onto the ship at port and you take over from there, or EXW (Ex Works) where you pick up from the factory, or CIF where the supplier covers cost, insurance, freight to your port, etc. Understanding your term is important so you know who is booking the main transport. For example, if it’s FOB Shanghai, your supplier will get the goods through Chinese export customs and onto a vessel you nominate. If it’s EXW, you (or your forwarder) must collect the goods from the factory and handle everything after. Jane’s order was FOB, so her supplier trucked the planners to Shanghai port and handled export clearance, while Jane’s freight forwarder arranged the ocean shipping from Shanghai to Seattle.

Tracking and Timing

Once in transit, tracking your shipment is crucial so you can prepare for its arrival. Freight forwarders typically provide tracking updates or an online portal. Ocean freight will have milestones like “departed port”, “arrived at destination port”, etc. Keep an eye on these. At this stage, logistics is about coordination and timing – ensuring that when the vessel arrives, you’re ready on the receiving end. For a smooth experience, double-check that all shipping documents (bill of lading, packing list, commercial invoice, etc.) are in order and sent to whoever will handle customs for you. The end-to-end approach really shows its value here: it’s not just shipping, it’s making sure the right paperwork and plans are in place so the goods flow without hiccups. As one industry source puts it, managing the logistics from supplier to business involves coordinating transport, handling customs, and ensuring timely delivery of goods to their final destination – a lot of pieces that need to come together.

Stage 7: Customs Clearance and Importing

As your goods arrive in your country, they must go through customs clearance. Stage 7 focuses on importing and customs, which is a critical juncture in the journey. Navigating customs might sound intimidating to newcomers, but if you’ve prepared the paperwork and know the basics, it usually goes smoothly.

Customs Documentation

By the time the shipment is on its way, you should have a set of documents needed for import. These typically include:

- Commercial Invoice (from the supplier, listing the goods and value),

- Packing List (details of the shipment contents and package dimensions),

- Bill of Lading or Air Waybill (the transport document from the carrier),

- Any applicable certificates (for example, certificates of origin, or compliance certificates if required for your product type).

Provide these documents to your customs broker or agent who will handle the clearance. If you’re a small importer, it’s highly recommended to use a customs broker – they are licensed experts who communicate with customs on your behalf, ensure duties are calculated correctly, and file the needed declarations. Many freight forwarders offer customs brokerage services or can refer you to one.

Paying Import Duties and Taxes

When goods clear customs, you’ll need to pay any import duties, taxes (like VAT or GST if applicable, or in the U.S., import tariffs plus possibly state taxes if not deferred), and fees. The duty rate depends on the product category (classified by an HS code) and the country of origin due to trade agreements. Part of planning in Stage 1 is checking these rates so you aren’t surprised by the costs. For example, Jane looked up that journals and paper products have a low duty rate into the U.S., but if you’re importing say electronics, the tariffs might be higher. Once customs calculates the amount, the broker will usually ask you to wire the payment or they might have you on account. Prompt payment ensures no delays in releasing the goods.

Regulatory Compliance

Customs may also enforce compliance checks. Depending on the product, there could be safety standards or regulations (for instance, FDA regulations for food-related products or FCC certification for electronics). If you’ve done your homework in the planning stage and ensured your supplier provided necessary certificates, you’ll be prepared. Occasionally, customs might select a shipment for inspection – which could be random or due to some red flag. If that happens, don’t panic; your broker will guide it through, though it might add a few days. It underscores why thorough documentation and truthful declarations are important.

Clearing and Pick-up/Delivery

Once cleared, your goods are officially imported. If it’s coming by sea, often the goods will go to a warehouse or distribution center after the port until you arrange pickup or delivery. If by air, they’ll be at an airport warehouse. You typically have a destination handling fee and warehouse fee to pay as well. Coordinate with your freight forwarder or warehouse on either delivering the goods to your final address or picking them up. In an end-to-end service scenario, this is taken care of seamlessly – you might even have the goods delivered directly to your door or fulfillment center without you having to lift a finger. For example, Jane’s forwarder handles everything and a truck drops off the pallet of planners at her storage unit a couple days after port clearance. She didn’t have to personally go to the port or deal with customs officers at all.

By the end of Stage 7, your product has legally entered your country and is ready for you to take possession. This stage can be nerve-wracking the first time, but with the right partners (forwarders and brokers) and preparation, it’s usually routine. Many entrepreneurs breathe a sigh of relief once they hear “Cleared by customs!”

Stage 8: Final Delivery and Next Steps

The journey concludes with Stage 8: Final Delivery – getting the products into your hands (or your warehouse) and reflecting on the process for future improvement. At this point, your goods have arrived. Congratulations! But there are still a few things to wrap up in this last mile.

Receiving and Checking Goods

When the shipment is delivered, it’s wise to verify the goods one more time. Do a count to ensure you received the right quantity of boxes or pallets. Open up some cartons and inspect the products to make sure nothing got damaged in transit and the goods still match the quality from the factory. If you find any major problems at this stage (like water damage, missing items, etc.), document it immediately and inform your supplier or insurance/freight company as appropriate. In most cases, if you did thorough QC earlier, this is just a formality and you’ll find everything as expected.

Warehousing or Fulfillment

Next, move your products to wherever they need to go to reach customers. That could be your own warehouse, a retail store, or a fulfillment center (such as Amazon FBA if you’re an e-commerce seller). Organize your inventory, label units if needed, and prepare them for sale. For an Amazon seller, for example, this might involve creating product listings and sending units to Amazon’s warehouses. For a retail operation, it might mean distributing stock to stores. Essentially, this step transitions from sourcing into your sales and distribution workflow.

Review Supplier Performance

A hallmark of end-to-end thinking is not just stopping at delivery, but also reviewing how everything went. Take some time to evaluate the overall process and supplier performance. Was the quality up to par? Did the supplier respect timelines? How smooth was communication? This review will inform your next steps – whether you’ll reorder from the same supplier or need to seek improvements. Many businesses conduct a formal post-project review internally. In fact, performance review and continuous improvement is considered a key part of the sourcing cycle; companies that do this regularly see improved supplier relationships and product quality over time. You can provide feedback to the supplier as well (constructively). Good suppliers appreciate long-term partnerships and will welcome suggestions to serve you better on the next order.

Plan for the Next Cycle

Sourcing is a cyclical process. Now that one full cycle (from idea to delivery) is complete, use what you’ve learned to plan the next one. Maybe demand was higher than expected, so you need to order a larger batch. Or perhaps you discovered a new feature to add in the next production run. Also, consider if there are any steps you’d handle differently to be more efficient next time. As your business grows, you might implement more automation or tools – for example, inventory management software that ties into reordering, or using an online platform to manage communications. The end-to-end mindset encourages you to see sourcing as an ongoing, improving process, not a one-and-done task.

In Jane’s case, after selling out her planners, she reviewed the journey. The supplier did a great job on quality but the process took a bit longer than she hoped. Next time, she plans to start the process earlier and perhaps use a faster shipping method for part of the shipment to meet early demand. She also decided to stick with the supplier for a reorder, since the relationship proved solid. Jane’s end-to-end approach – from careful planning to diligent QC – paid off with a successful product launch, and now she can iterate and scale with confidence.

Key Roles in the Sourcing Process

Throughout the end-to-end sourcing journey, several key players (roles) are involved. It’s helpful to know who does what, especially if you’re new to importing. Sometimes one person or company might cover multiple roles (for example, an end-to-end sourcing service might handle many of these for you), but here are the main roles and their contributions:

Importer (You)

The buyer of the goods. You initiate the project, make decisions, and often coordinate the process (unless you outsource management). You define product requirements, approve samples, and ultimately sell the product. In a small business, the owner or manager might wear multiple hats, overseeing everything from supplier communication to logistics arrangements.

Sourcing Agent / Sourcing Company

A specialist or firm that helps find and vet suppliers, especially useful if you’re sourcing from overseas and need on-the-ground expertise. They can handle supplier research, negotiations, and even order follow-up. Essentially, a good sourcing agent is your guide through the maze, using their network and knowledge to secure reliable manufacturers. For example, a U.S. company might hire a China-based sourcing agent to manage factory selection and communication in the local language.

Supplier / Manufacturer

The company actually making your product. This could be a factory or a trading company. They are responsible for producing goods to your specifications and on schedule. Building a good relationship with the supplier is crucial; they are a core part of your supply chain. In an end-to-end service context, you might not interface with the supplier directly as much, but they are still the ones creating your product.

Quality Control Inspector

Either an individual or team that checks the product quality. This can be independent third-party inspectors or an internal QC team at the sourcing company. They conduct inspections (during production and/or before shipment) to ensure the goods meet your standards. Their role is to catch defects and issues so they can be corrected before you receive the products. Quality inspectors act as your eyes on the factory floor when you can’t be there in person.

Freight Forwarder

A logistics expert or company that arranges the transportation of goods. They coordinate with carriers (shipping lines, airlines, trucking companies) to ship your products from A to B. Forwarders handle the complex details of freight booking, consolidation, export paperwork, and often customs clearance on the destination side. They are key to the logistics stage – think of them as travel agents for your cargo.

Customs Broker

A professional or firm licensed to handle customs clearance in the importing country. They prepare and submit the required customs documents, classify your goods for tariffs, and liaise with customs authorities to get your shipment cleared. In many cases, the freight forwarder will also offer customs brokerage, but it’s listed as a distinct role because it requires specialized knowledge of import regulations and tariff codes in your country.

Warehouse / Fulfillment Provider

Once goods arrive, if you’re not storing or handling distribution yourself, you might use a warehouse or fulfillment service. They receive your inventory, store it, and possibly pack and ship orders to your customers (in the case of a fulfillment center). While not part of “sourcing” per se, they are the next link in the chain from factory to customer. For e-commerce sellers, Amazon FBA or 3PL (third-party logistics) companies fall in this category.

Each of these roles plays a part in the end-to-end chain. End-to-end sourcing services often bundle many of these roles together – for example, a full-service provider might act as your sourcing agent, coordinate QC, and arrange freight and customs, essentially handling everything except the selling of the product. As a business owner, understanding these roles helps you decide which parts you can handle yourself and where you might want help. The end goal is the same: a smooth process from idea to delivered product, with all players working in sync.

Key Takeaways

- Sourcing is a Journey: Think of product sourcing as an end-to-end journey rather than isolated tasks. Starting from clear research and ending at delivery (and beyond), each stage is connected. Missing a step can cause issues later, so plan for every part of the process.

- Preparation and Vigilance Pay Off: Investing time in early stages (like thorough planning and supplier vetting) and being vigilant during production (with quality inspections) prevents costly problems. It’s easier to tackle issues early than to fix a disaster after the fact.

- Use the Right Partners: You don’t have to go it alone. Sourcing agents, quality inspectors, freight forwarders, and brokers exist to help. An end-to-end service or a combination of trusted partners can handle the heavy lifting of coordination, especially for international trade, letting you focus on your business.

- Communication is Key: Smooth collaboration with suppliers and service providers is crucial. Keep communication clear and documented at every stage. This ensures everyone understands expectations and can react quickly if something changes (like a production delay or a shipping schedule shift).

- Continuous Improvement: After completing a sourcing cycle, review the process. Learn from any hiccups and identify what went well. Over time, your sourcing process will become more refined and efficient. For growing businesses, continuously improving your end-to-end sourcing approach is how you scale successfully while maintaining quality and control.

Conclusion

End-to-end sourcing is all about seeing the big picture of bringing a product from concept to reality and managing each step thoughtfully. By breaking down the sourcing journey into stages and handling each with care, even a small entrepreneur can operate with the efficiency of a seasoned sourcing manager. We’ve seen how planning, careful supplier selection, quality control, and logistics coordination all link together. It may seem like a lot of moving parts, but with an organized approach (and help from experts where needed), it becomes a manageable, repeatable process.

For beginners, the idea of dealing with overseas suppliers, inspections, and shipping might feel daunting – but an end-to-end framework turns it into a step-by-step roadmap. For growing businesses, this approach is what allows you to scale your supply chain without letting things slip through the cracks. In short, end-to-end sourcing brings peace of mind that from the first spark of a product idea to the moment it lands in your inventory, every step is handled. With knowledge, preparation, and the right support, you can navigate the sourcing world confidently and watch your business thrive. Happy sourcing!