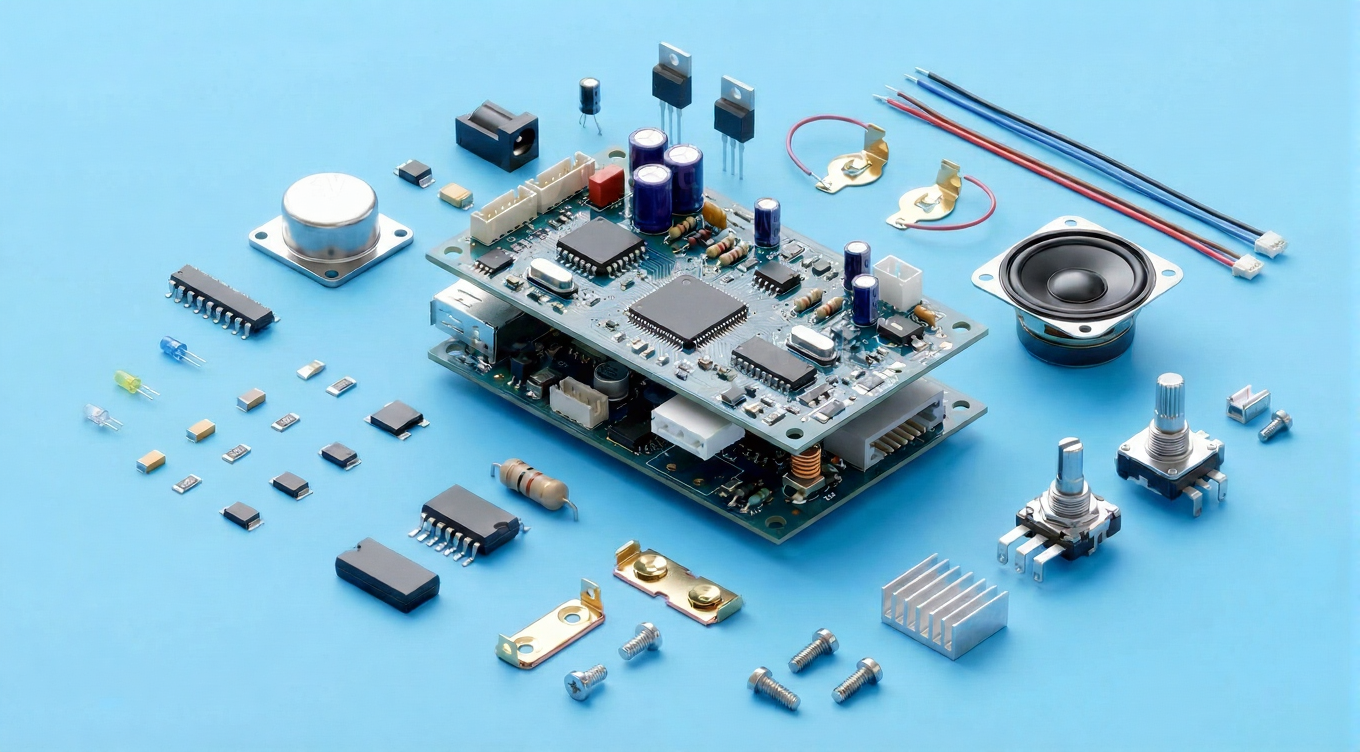

Many appliances look simple on the outside, but inside they house critical components like motors, heating coils, circuit boards, and sensors. These hidden parts determine safety and performance. A wire that’s too thin, a coil that isn’t rated for proper voltage, or a counterfeit chip can mean motor burnout, overheating, or fires. For example, an exploded view of an appliance motor reveals springs, coils and metal parts that must all meet exact specs – if a supplier uses cheaper materials, the motor may overheat or seize under stress. Cutting corners on any internal part means a much higher risk of failure, often without any visible sign until it’s too late.

Small Kitchen Appliances (Blenders, Air Fryers, Rice Cookers)

In small kitchen gadgets, quality of internal parts is everything. A blender’s cheap motor may burn out under a heavy load; an air fryer with a low-grade thermostat or under-rated heating coil can overheat or trip the safety fuse prematurely. Poor insulation or wiring in rice cookers can cause short circuits or fires. Inspectors often check that wires, PCBs and heating elements match the specified material and ratings for voltage and temperature – these routine checks could catch many design defects. If not, the result can be a smoking appliance or a blown thermal fuse (as thousands of dehumidifiers had to recall after fires). Even a single failed component forces costly recalls and rebuilds.

- Motors & Fans: In countertop blenders or juicers, the motor runs constantly under torque. Cheaper motors run hotter and can burn out or jam if blades hit something hard.

- Heating Elements: In rice cookers and air fryers, the coil must handle hundreds of degrees repeatedly. A subpar element may warp or short, leading to fire hazards.

- Circuit Boards & Sensors: Smart kitchen devices use PCBs and temp sensors. A solder joint made with incorrect alloy or an uncalibrated sensor can cause the device to overheat or shut down unexpectedly.

In fact, quality issues in these components are often behind recalls. For example, a major Chinese appliance maker recalled 3.4 million dehumidifiers after reports of smoke and fire (about $4.8M damage) caused by faulty temperature controls and circuitsi. Similar wiring and insulation failures in small kitchen gadgets can be just as dangerous.

Home Electronics (Speakers, Fans, Remotes)

Everyday electronics hide critical parts too. Consider a Bluetooth speaker: a counterfeit power IC or an untested lithium battery can fail or catch fire under normal use. A stand fan with a cheap motor or flimsy oscillating switch can overheat or short out. A CPSC study on portable fans found that “the failure modes… were the fan motors, powered appliance cords, or switches.” Motors often failed when overheated by seized blades, and cords frayed or shorted as they rubbed against fan partscpsc.gov. Even a simple remote control can fail early if its circuit board or IR LED is substandard.

- Wireless Modules: FCC rules require certified radios. Cheap speakers using unapproved wireless chips can fail EMC tests or even be banned from sale.

- Wiring & Connectors: A short in a fan cord or speaker cable can create fire or shock hazards. UL specifically warns that using “uncertified, counterfeit or inferior… wiring” in appliances introduces “significant safety hazards” and raises the risk of “costly and brand-damaging recalls”.

- Switches & Sensors: Cheap push-buttons or thermal sensors may break or misread. For example, a faulty temperature sensor in an air purifier might not shut off a heater, leading to overheating.

Bottom line: sub-par speakers, fans or remotes may work initially, but poor component quality leads to higher failure rates, safety incidents and warranty returns.

Battery-Powered Tools (Vacuums, Drills)

Cordless tools depend on reliable motors and batteries. A vacuum with a weak motor may burn out or stall, while a drill with a poor quality trigger switch can stick on and overheat. The CPSC recently warned consumers about a Chinese-made cordless drill brand after reports of drills “exploding, igniting, melting, smoking, or overheating,” causing property damage and injuries. These failures were traced to battery packs and charging circuitry that couldn’t handle normal use. Cheap lithium-ion cells or battery management circuits often have no safety margin, so an overload or short can cause fire. Similarly, counterfeit or unlabeled components can slip into chargers and inverters, leading to electric shock or explosions.

- Batteries & Chargers: Inferior lithium packs can swell, catch fire, or vent toxic smoke. Proper QC testing (charge/discharge, temperature cycling) is essential to avoid the kind of hoverboard fires we saw in past years.

- Motors & Gearboxes: High-current brushless motors in vacuums and drills require precise assembly. If shafts aren’t aligned or windings aren’t insulated correctly, the motor draws extra current and burns out.

- Safety Cutoffs: A cheap circuit breaker or thermal fuse may not trip at the right time, converting a minor overload into a runaway hazard.

Every part in these tools is hidden power – and if it fails, the tool can go from “convenient” to “hazard” in seconds.

Cutting Corners & Supplier Tricks

Chinese suppliers under cost pressure sometimes take shortcuts. Common “tricks” include using cheaper substitute parts or relabeling old stock. Without strict controls, a manufacturer might slip in a generic capacitor instead of the specified brand, or mix components from unauthorized suppliers. One quality expert warns that sourcing from “unauthorized suppliers” can turn into a “compliance disaster”: the product may unknowingly contain non-compliant parts, forcing you to halt production and hunt for correct componentss. Other pitfalls include ignoring the Bill of Materials (BOM) or Component Data Form (CDF). A good CDF lists approved part numbers and manufacturers; using it correctly “helps ensure [suppliers] don’t substitute inferior parts”. When these controls are absent, suppliers might install counterfeit chips, break the factory floor packaging rules, or skip incoming quality checks on critical parts. Each of these shortcuts saves money in the factory but shifts enormous risk downstream.

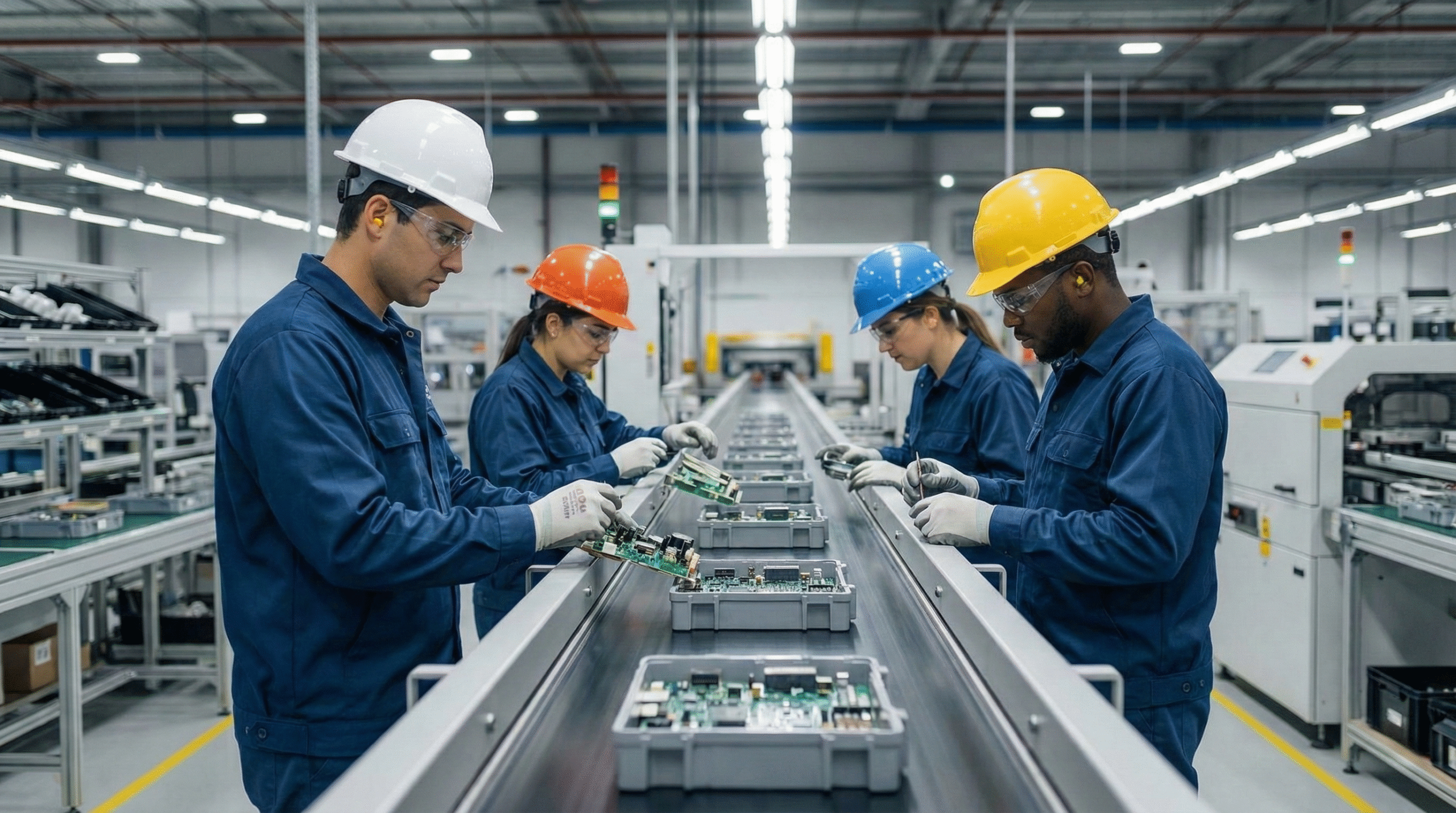

To prevent this, savvy importers demand detailed documentation. That means a locked-down BOM/CDF (to match components by data sheet) and factory audits of any subcontractors. As one QC guide notes, performing strict incoming inspections on components is crucial: “how can you expect good product quality if the contract manufacturer doesn’t do incoming checks on their parts?”. In practice this means inspecting PCBAs, wires, motors etc. before assembly, rather than guessing after the fact.

Failure Modes & Real Costs of Cheap Parts

When low-quality components fail, the consequences cascade. Electrical shorts can blow fuses or ignite fires; overheated coils can melt plastics and trip breakers. A tiny flaw in a printed circuit board or solder joint can disable an entire device. For instance, defective dehumidifiers were found to overheat due to shorts or insufficient heat dissipation, causing fires. In many cases, “more heat than expected is produced…often due to a short circuit… or poor heat dissipation”. These internal failures lead directly to returns and recalls.

The real-world costs are staggering. Consumer trust evaporates after one bad incident. A recall of even a few thousand units can cost millions (and sometimes the brand itself). Samsung’s famous Galaxy Note7 battery debacle cost over $5.3 billion in write-offs – and it was just one mobile product line. In appliances, recalls still hit hard: a 2017 Midea dehumidifier recall saw ~$4.8M in damages from fires. Even without a full recall, warranty repairs and replacements inflate costs. Add on negative online reviews and lost future sales, and the business impact can be crushing.

Moreover, regulators do not turn a blind eye. UL and FCC standards are strict. If a hidden component is out of spec, your product can fail certification. In fact, recent news shows U.S. retailers delisted millions of Chinese-made devices because they lacked proper FCC authorization. A small oversight – say, a non-UL wire or a non-certified radio module – can mean a total sales ban in the U.S. Understanding UL, FCC, CE, and other requirements for each part is as important as testing the final appliance.

The Impact on Brand, Trust and Compliance

Poor internal component quality undermines brand reputation. Customers expect kitchen gadgets and electronics to last years. When motor bearings seize or an air fryer burns out prematurely, word spreads fast on social media and review sites. High return rates trigger penalties on ecommerce platforms like Amazon. Even if only 1–2% of units fail, that’s hundreds of angry customers and lost trust. Meanwhile, regulatory bodies track incidents: multiple fire or shock reports can invite costly CPSC investigations or recalls.

UL solutions warns that substandard wiring or parts not only pose direct hazards but also put your entire brand at risk of “costly and brand-damaging recalls”. Quality failures often mean replacing entire production runs, not just the faulty part. This is why top brands insist on rigorous QA at the part level. They know a cheap $0.10 piece can end up costing thousands if it causes a drop in sales or a legal fine.

Household Appliance Sourcing Tips

To manage these risks, follow strict sourcing and QC protocols. Key tips include:

- Lock down your BOM/CDF. Specify every critical part in writing (approved manufacturers, part numbers, datasheets). Require your factory to check every component against this list before assembly.

- Inspect parts and processes on-site. Don’t wait for final products – perform regular incoming quality control (IQC) on batches of motors, PCBs, coils and sensors. Conduct pre-shipment inspections to catch defects. As one QC expert notes, inspecting a shipment before it leaves the factory is one of the best ways to uncover nonconformities and avoid recalls.

- Verify certifications. Only source parts that meet UL, FCC or CE standards as required. Ask for certification documents (UL marks on wires, FCC IDs on radios) and verify them independently.

- Audit and qualify suppliers. Vet your contract manufacturers and their sub-suppliers. Factory audits ensure that the supplier’s quality system and maintenance schedules are up to par.

- Test product samples under real conditions. Simulate heavy use and abuse tests in the QA lab or factory. Even brief run-time tests can reveal failed overheats or shorts.

- Maintain documentation. Keep sample records, test reports, and traceability for each batch of components – this pays off if a problem later needs root-cause analysis.

These “household appliance sourcing tips” help ensure every hidden component meets spec. Treat internal parts with the same scrutiny as final product features

Building quality into your supply chain requires local expertise. That’s where China Direct Source comes in. Our team provides part-level quality assurance from factory to shipment. We verify each motor and PCB against your standards, conduct on-site inspections, and ensure compliance (UL/FCC) before goods ship. Partnering with us means you don’t have to trust luck – you can trust independent verification. With China Direct Source, you protect your brand’s reputation and deliver safe, reliable appliances that customers love.

Take action: Don’t let cheap components undermine your appliance line. Reach out to China Direct Source today to implement rigorous quality controls in your China supply chain – and rest easy knowing every part is up to the task.